The CFW500 manual is a comprehensive guide for installing, operating, and maintaining the inverter․ It ensures safe and efficient use, covering key aspects for users․

1․1 Purpose and Scope of the Manual

This section outlines the purpose and scope of the CFW500 manual, providing essential information for safe and effective use․ It covers installation, operation, and maintenance, targeting users with basic technical knowledge․ The manual ensures compliance with safety standards and includes troubleshooting guides, technical specifications, and compliance details․ It serves as a primary resource for understanding and optimizing the CFW500 inverter’s performance and functionality․

1․2 Target Audience and Prerequisites

This manual is designed for engineers, technicians, and maintenance personnel involved in the installation, operation, and maintenance of the CFW500․ Basic knowledge of electrical systems, inverters, and motor control is assumed․ Users should familiarize themselves with safety protocols and technical specifications before proceeding․ Advanced programming skills are not required, though familiarity with inverters or PLCs is beneficial for optimizing functionality and troubleshooting․ Adherence to safety guidelines is essential․

Installation and Setup of the CFW500

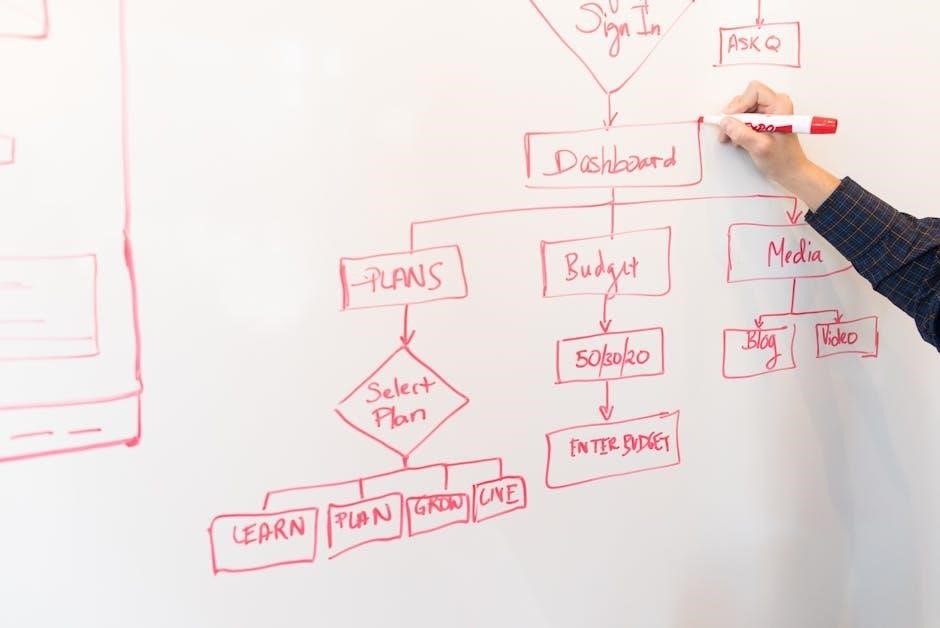

This chapter provides step-by-step instructions for installing and setting up the CFW500, covering power connections, wiring diagrams, control configurations, and a quick setup guide for easy initialization․

2․1 Power Connections and Wiring Diagrams

The CFW500 requires proper power connections to ensure safe and efficient operation․ The manual provides detailed wiring diagrams for 1-phase and 3-phase power supplies, including voltage options like 200-240V and 380-480V․ It also outlines the necessary steps for connecting control circuits and ensures compliance with safety standards․ Always refer to the diagrams for specific configurations and grounding requirements to prevent electrical hazards․

2․2 Control Connections and I/O Configuration

The CFW500 supports various control connections, including digital inputs and outputs, to enable seamless integration with external devices․ The manual provides detailed wiring diagrams and configuration steps for I/O setup․ Optional modules, such as the I/O expansion module, can be installed to enhance connectivity․ Proper configuration ensures precise motor control and safe operation, adhering to the inverter’s technical specifications and application requirements․

2․3 Quick Setup Guide for First-Time Users

This section offers a step-by-step guide for first-time users to quickly commission the CFW500․ It includes connecting power, configuring basic parameters, and initializing the inverter․ The guide emphasizes essential settings like motor frequency and voltage, ensuring a smooth startup․ Detailed diagrams and troubleshooting tips are provided to address common issues, making the process efficient and user-friendly for those new to the system․

Programming and Configuration

This section covers the programming and configuration processes for the CFW500․ It includes basic parameter settings, advanced functions, and HMI usage for optimal performance and control․

3․1 Basic Parameter Settings (P0204, P0205, P0206)

The basic parameter settings for the CFW500 include P0204, P0205, and P0206․ These parameters are essential for configuring the inverter’s fundamental operations․ P0204 sets the base frequency, either 50 or 60 Hz, depending on the application․ P0205 configures the motor voltage, ensuring compatibility with the connected motor․ P0206 defines the motor frequency, which must match the motor’s specifications for optimal performance․

These settings are typically configured during the initial setup and are critical for ensuring proper operation․ Adjusting these parameters incorrectly can lead to motor malfunction or inverter errors․ Always refer to the programming manual for detailed instructions and safety guidelines when modifying these settings․

3․2 Advanced Programming Functions and HMI Usage

The CFW500’s advanced programming functions allow for tailored control strategies using the HMI interface․ Users can access and modify parameters like P0204, P0205, and P0206 for customized operation․ The SoftPLC module enables programmable logic for complex applications․ The HMI simplifies navigation and configuration, offering real-time monitoring and adjustments․ For detailed instructions, refer to the programming manual to ensure proper setup and safe operation of advanced features․

Operation and Control Modes

The CFW500 supports multiple control modes, including V/F, VVW, and vector control, offering flexible operation for various applications․ These modes ensure optimal motor performance and efficiency․

4․1 V/F, VVW, and Vector Control Modes

4․1 V/F, V/F, and Vector Control Modes

The CFW500 offers three primary control modes: V/F (Volts per Hertz), VVW (Variable Voltage, Variable Power), and Vector control․ V/F is ideal for basic applications, providing a linear voltage-to-frequency relationship; VVW enhances torque control at low speeds, while Vector control delivers high precision for demanding motor applications․ Each mode ensures optimal performance across various motor types and operational demands, allowing users to tailor settings for specific requirements․ These modes are easily selectable via the HMI, providing flexibility and efficiency in operation․

4․2 Motor Control Types and Application Examples

The CFW500 supports various motor control types, including induction and synchronous motors․ Induction motors are ideal for general applications, while synchronous motors offer higher efficiency․ Typical applications include pumps, compressors, and conveyor systems․ The inverter’s flexibility allows it to adapt to diverse industrial needs, ensuring precise control and energy efficiency in each application, making it suitable for both standard and specialized motor-driven systems․

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance and longevity of the CFW500․ Clean the inverter, check connections, and monitor for errors․ Troubleshooting involves diagnosing alarms and verifying parameters․ Always refer to the manual for detailed procedures and solutions to common issues․ Proper maintenance enhances reliability and minimizes downtime in industrial applications․

5․1 Routine Maintenance and Inspection

Regular maintenance is crucial for the CFW500’s optimal performance․ Inspect the inverter’s cooling fans, clean dust from heat sinks, and ensure all connections are secure․ Check for loose terminals, worn-out cables, and signs of overheating․ Use compressed air to remove dust without damaging components․ Verify parameter settings and update firmware as needed․ Schedule inspections every 6 months and after prolonged downtime to maintain efficiency and reliability;

5․2 Common Errors and Diagnostic Procedures

Common errors include parameter mismatches, overheating, and communication faults․ Check error codes like F0248 for data exchange issues and ensure proper Ethernet connections․ Verify parameter settings, especially P0204, P0205, and P0206, using the HMI․ Inspect for loose connections and dust buildup․ Consult the manual for specific diagnostic steps and solutions to restore functionality and prevent downtime․ Regular checks help identify issues early, ensuring smooth operation․

Safety Precautions and Warnings

Always wear protective gear and avoid contact with live circuits․ Follow all safety guidelines to prevent injury or equipment damage․ Ensure proper training before operation․

6․1 General Safety Guidelines

Always follow safety guidelines when working with the CFW500․ Wear protective gear, avoid contact with live circuits, and ensure proper training․ Disconnect power before maintenance․ Use appropriate tools and adhere to local regulations․ Never bypass safety features or attempt unauthorized modifications․ Ensure proper grounding and cabling․ Follow all warnings and cautions in this manual to prevent injury or equipment damage․ Safety is paramount for successful operation․

6․2 Emergency Procedures and Fault Handling

In case of an emergency, disconnect power immediately and follow safety protocols․ Identify fault codes displayed on the HMI for troubleshooting․ Check connections and restart the system if necessary․ Refer to the manual for detailed diagnostic procedures and solutions․ Always prioritize safety and proper fault handling to prevent further issues and ensure reliable operation of the CFW500 inverter․

Technical Specifications

The CFW500 inverters offer power ratings up to 25 kW, with voltage options including 1-phase (200-240 V) and 3-phase (200-240 V, 380-480 V, 575 V), ensuring versatility for various applications․

7;1 Power Ratings and Voltage Options

The CFW500 series offers a wide range of power ratings, from 0․25 kW to 25 kW, ensuring compatibility with various industrial applications․ Voltage options include 1-phase (200-240 V) and 3-phase (200-240 V, 380-480 V, 575 V), providing flexibility for different power supply systems․ These configurations allow the inverter to operate efficiently in diverse environments, meeting the demands of applications such as compressors, pumps, and conveyors while maintaining optimal performance and energy efficiency․

7․2 Compatibility and Application Range

The CFW500 is designed for a wide range of applications, including compressors, conveyers, and pumps, ensuring versatility in industrial settings․ It supports various motor types and is compatible with multiple control modes, making it suitable for both simple and complex systems․ Its robust design allows operation in harsh environments, catering to industries such as manufacturing, agriculture, and water treatment, ensuring reliable performance across diverse operational needs and conditions․

Certifications and Compliance

The CFW500 complies with international standards and certifications, ensuring safety and environmental regulations are met․ It holds certifications such as UL, CE, and ISO, guaranteeing global compatibility and adherence to industry norms․

8․1 Industry Standards and Certifications

The CFW500 meets various industry standards, including UL, CE, and ISO certifications․ These ensure compliance with global regulations for safety, environmental sustainability, and performance․ The certifications validate the inverter’s reliability and adherence to international quality benchmarks, making it suitable for diverse industrial applications․ Compliance with these standards is crucial for operational safety and environmental responsibility․

Accessories and Optional Features

The CFW500 offers optional modules, such as the CFW500-IOD for digital I/O, and communication modules for enhanced functionality․ These accessories expand the inverter’s application range and capabilities․

9․1 Optional Modules and Expansion Options

The CFW500 supports various optional modules, such as the CFW500-IOD for digital I/O expansion and communication modules for enhanced connectivity․ These modules allow users to tailor the inverter to specific applications, ensuring flexibility and scalability․ Additional expansion options include HMI interfaces and SoftPLC integration for advanced control capabilities․ The manual provides detailed information on module compatibility and installation procedures to maximize system performance and customization․

This concludes the CFW500 manual․ For further details, refer to the programming manual, technical specifications, and additional resources available online․ Safe operation and successful application are prioritized․

10․1 Additional Resources and Documentation

For deeper understanding and advanced operations, refer to the CFW500 programming manual, technical specifications, and quick setup guides․ Visit WEG’s official website for updated resources, troubleshooting tips, and compliance details․ These materials ensure safe and effective use of the inverter, covering all aspects from installation to maintenance․ Utilize these resources to maximize the CFW500’s performance and adaptability in various applications․